In the modern leather industry, leather grinding machines have become an indispensable piece of equipment. With the continuous increase in consumer demand and production efficiency, traditional manual leather processing is gradually being replaced by efficient, precise, and automated machinery. The leather grinding machine is a key driver of this transformation. It not only improves the quality and efficiency of leather processing, but also brings greater stability and controllability to the leather industry.

The emergence of leather grinding machines has solved several technical challenges in the leather-making process, particularly in leather surface treatment and quality control. Traditional manual grinding is not only time-consuming and labor-intensive, but also difficult to ensure consistency, often resulting in inconsistent quality in the finished leather. The introduction of leather grinding machines, through mechanized operation, has effectively improved production efficiency and product quality. Especially in large-scale production, leather grinding machines provide the leather industry with a reliable automated solution, increasing production line speed while reducing labor costs and operational risks.

The Core Role of Leather Grinding Machines in the Leather Industry

Leather grinding machines play a vital role in the leather industry, particularly in the following areas:

Improving Production Efficiency: With the leather industry's ever-increasing demand for production efficiency, leather grinding machines, with their high speed and high efficiency, have become an "accelerator" on the production line. Manual grinding requires workers to spend considerable time and effort on rough grinding, fine grinding, and final gloss treatment of leather. The advent of leather grinding machines has automated and mechanized these processes. Using high-speed rotating grinding discs or belts, excess leather surface material is quickly removed, improving smoothness and significantly increasing production efficiency. Whether in small-scale custom production or large-scale industrial production, leather grinding machines ensure stable and efficient production output.

Improving Leather Surface Quality: The surface quality of leather is crucial to the aesthetics, durability, and market competitiveness of the finished product. By precisely controlling the grinding process, leather grinding machines achieve a uniform finish on the leather surface, eliminating blemishes and unevenness caused by dyeing, processing, or storage. Especially in the production of high-end leather products (such as luxury handbags, shoes, and car seats), surface quality requirements are extremely stringent. The high precision of the grinding machine ensures that each piece of leather has a pristine finish, providing consumers with a superior product experience.

Precise Control of the Process: Traditional manual grinding often results in inconsistent leather surface finish quality due to differences in operator skill levels. Leather grinding machines utilize advanced CNC technology and sensors to precisely control the force, speed, and angle of the grinding, ensuring consistent and precise grinding for each piece of leather. This high level of controllability not only effectively eliminates human error but also improves the stability of the production process, resulting in more reliable finished product quality.

Reduced Production Costs: Although the initial investment is high, leather grinding machines offer significant long-term cost savings for the leather industry. First, automated operation reduces reliance on manual labor, reducing labor costs. Second, the grinding machine's efficiency and precision reduce leather waste and the need for rework, thereby reducing raw material consumption and production losses. Furthermore, grinding machines not only improve production efficiency but also reduce defective product rates, further enhancing business profitability.

Promoting Environmental Protection and Resource Utilization: With increasingly stringent environmental protection requirements, the leather industry is under pressure to reduce pollution and improve resource utilization efficiency. Leather grinding machines demonstrate their environmental advantages in this regard. Compared to manual grinding, leather grinding machines effectively control the emission of waste (such as leather dust) generated during the leather grinding process. Many modern grinding machines are also equipped with advanced dust recovery systems, reducing environmental pollution. Furthermore, the precise grinding process reduces raw material waste and improves resource utilization.

Adaptable to Diverse Leather Types: The versatility and flexibility of leather grinding machines enable them to adapt to the processing needs of different leather types. Whether natural or synthetic, the grinding machine can adjust grinding parameters based on the physical properties of the leather to achieve optimal results. Modern leather grinding machines can also precisely adjust the thickness, flexibility, and other characteristics of the leather to meet the needs of different industries and products.

Basic Concepts of Leather Grinding Machines

A leather grinding machine is a type of industrial equipment specifically designed for treating the surface of leather. It is widely used in tanning, leather processing, and the production of leather products. Its primary function is to mechanically polish, smooth, and trim the leather surface, removing blemishes, burrs, and uneven areas to enhance the leather's gloss, smoothness, and tactile feel. This equipment not only significantly improves production efficiency but also ensures the high quality of leather products and reduces the instability associated with manual operation, making it an indispensable piece of equipment in modern tanneries.

Leather grinding machines are widely used in various industries, including footwear, clothing, furniture, and automotive seating. They are particularly effective for leather products requiring high-quality finishes, such as high-end leather and art leather. Due to its high efficiency, precision, and controllable features, leather grinding machines not only play a vital role in traditional tanning processes but have also become a crucial tool for advancing leather processing technology.

Main Functions of a Leather Grinding Machine

The functions of a leather grinding machine can be categorized based on different processing requirements, primarily encompassing the following aspects:

Surface Smoothing and Polishing: One of the basic functions of a leather grinding machine is to smooth and even the surface of leather through grinding and polishing. This not only improves the appearance of the leather, making it more polished, but also facilitates uniform coloring during subsequent dyeing or coating processes.

Removing Defects and Irregularities: During the leather production process, surface defects such as stains, spots, and scratches may appear. A grinding machine can help remove these irregularities, ensuring that the leather surface meets the highest quality standards.

Trimming and Thickness Leveling: A leather grinding machine can finely adjust the grinding force and speed to adjust the thickness of the leather, ensuring uniformity across each piece. This is particularly important for subsequent processing, especially when leather splicing or pressing is required.

Improving the feel and texture of leather: Through precise grinding, a leather grinding machine can improve the feel of leather, making it softer or tougher, meeting the diverse needs of different customers for leather products. For high-end leather products such as handbags and shoes, the quality of the surface feel directly impacts the consumer's purchasing experience.

Surface Modification and Decoration: In some high-end leather processing applications, leather grinding machines can also be used to create unique textures or effects, such as bas-relief effects and varying depths of leather grain. These detailed modifications help enhance the visual appeal and market competitiveness of leather products.

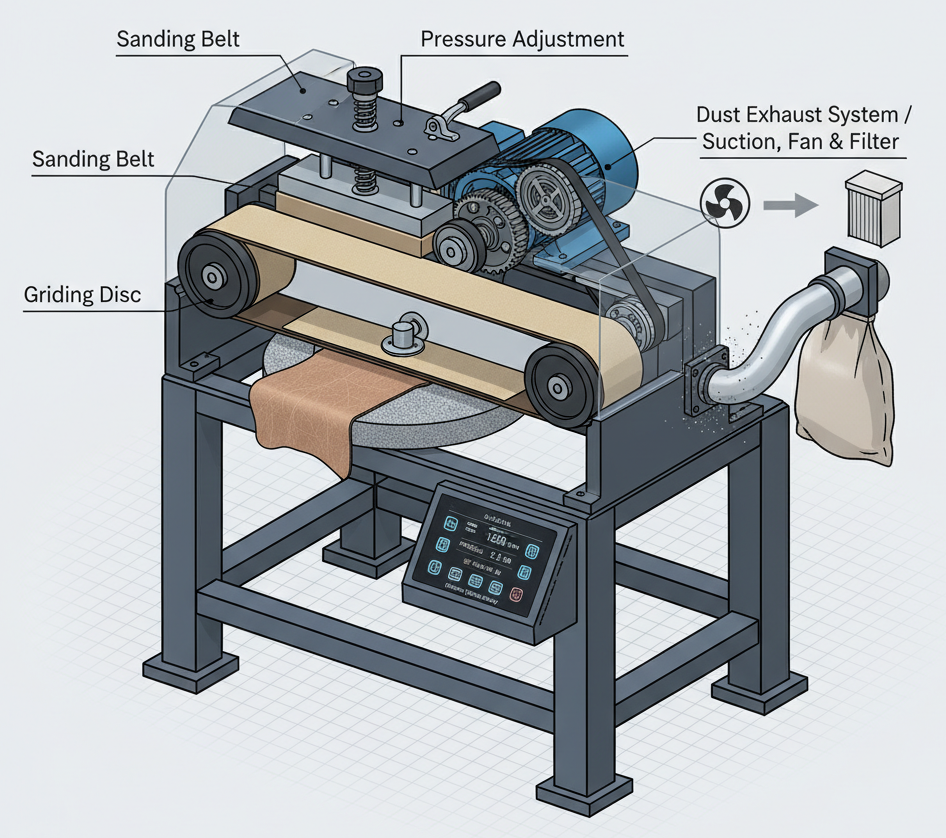

Basic Structure and Components of a Leather Grinding Machine

The design and construction of a leather grinding machine typically includes several core components. The following are the main components:

Grinding Disc (or Sanding Belt)

The grinding disc or sanding belt is the core component of a leather grinding machine and is directly involved in the leather grinding process. Depending on the specific requirements, the grinding disc typically comes in different materials, grits, and shapes to suit the sanding requirements of different leather types.

Belt Sanding: Sanding with a belt typically achieves a finer finish and is suitable for most common leather sanding processes. The grit of the sanding belt can be selected based on the type of leather and the intended sanding purpose. Coarse belts are used to remove larger surface imperfections, while fine belts are used for delicate polishing and finishing.

Disc Sanding: Some leather grinding machines use rotating abrasive discs instead of belts. These discs are typically harder and suitable for high-intensity sanding. The discs are coated with abrasive particles of varying coarseness and fineness, which can be replaced and adjusted as needed.

Drive System

The drive system of a leather grinding machine provides power to rotate the abrasive disc or belt. The drive system typically consists of components such as a motor, belts, gears, and bearings. In modern leather grinding machines, the drive system is typically electric, offering high efficiency and low energy consumption. Furthermore, the stability and accuracy of the drive system directly impact the leather sanding results.

Motor: The motor is the primary power source of the leather grinding machine and is typically a high-efficiency motor to provide stable power. Drive Belts and Gears: Belts or gears transmit the motor's power to the grinding disc or belt, ensuring smooth operation.

Adjustment System

Leather grinding machines are typically equipped with an adjustment system for adjusting the speed, pressure, and angle of the grinding disc or belt. Different leathers and processing requirements require different grinding parameters, so the adjustment system plays a crucial role in ensuring processing accuracy.

Speed Adjustment: Leather grinding machines allow the operator to adjust the grinding speed according to their needs. For coarse grinding, a lower speed is generally used, while fine grinding requires a higher speed.

Pressure Adjustment: The level of pressure directly affects the depth and effectiveness of the grinding process. Adjusting the pressure allows for flexible adjustments based on the type of leather and processing requirements, ensuring that each piece of leather is treated evenly.

Frame and Support System

The frame of a leather grinding machine is the supporting structure for all components and is typically constructed of high-strength metal to ensure stability and durability. The support system ensures that the grinder does not vibrate during high-load operation, preventing uneven grinding caused by vibration.

Dust Exhaust System

The grinding process generates a large amount of leather dust and debris. This dust not only pollutes the environment but can also pose a health risk to operators. Therefore, modern leather grinding machines are typically equipped with dust extraction systems to effectively absorb and remove dust generated during the grinding process. These systems typically include suction ports, fans, filters, and other components to ensure a clean factory environment and worker safety.

Control Panel

The control panel is the primary interface for operating the leather grinding machine. The operator uses it to adjust various machine parameters, such as speed, pressure, and time. Modern leather grinding machine control panels are typically touchscreen-style, equipped with a digital display and intelligent control functions, allowing the operator to monitor and adjust machine status in real time.

Working Principle of a Leather Grinding Machine

The operating principle of a leather grinding machine primarily relies on mechanical power. A high-speed rotating grinding disc, abrasive belt, or other abrasive material rubs against the leather surface, removing unevenness and imperfections and improving its smoothness and appearance. Different types of leather grinding machines utilize different power sources and operating methods. While the principles are similar, they differ in details. Understanding these operating principles is crucial for selecting and using a leather grinding machine.

Mechanical Power of a Leather Grinding Machine

A leather grinding machine uses mechanical power to drive a grinding disc or abrasive belt at high speed, generating strong friction and thus grinding the leather. Typically, a leather grinding machine is powered by an electric motor, which transmits power to the grinding disc or abrasive belt through a transmission mechanism such as belts and gears, driving it to rotate at a steady speed.

The operating principle of a grinding machine can be divided into two core components: friction and cutting.

Friction: During the grinding process, friction is generated when the grinding disc or abrasive belt contacts the leather surface. This friction not only removes rough materials from the leather surface but also removes blemishes and unevenness through subtle friction.

Cutting Action: Simultaneously, the grit (such as aluminum oxide and silicon carbide) attached to the abrasive disc or belt acts as a cutting mechanism, shaving off tiny portions of the leather surface. As the abrasive wears and is replaced, the cutting action becomes finer, and the polishing effect gradually becomes apparent.

Facts such as the motor speed, the disc material and grit size, and the leather's hardness all influence the polishing effect and processing efficiency. By adjusting these factors, the leather grinding machine can remove excess material while maintaining the integrity of the leather, achieving the desired finish.

Disc-Leather Contact and Force Principle

In a leather grinding machine, the contact between the disc and the leather surface is a key factor influencing the polishing effect. There are two common contact methods: direct and indirect.

Direct Contact: In a rotary grinder, the disc directly contacts the leather surface, typically at a vertical or angled angle. The high-speed rotation of the abrasive disc drives the sand grains into friction with the leather surface, producing a cutting and sanding effect. In this method, the frictional force on the leather surface primarily removes excess surface layers and smoothes the surface.

How it works: During contact between the abrasive disc and the leather, the disc's rotational speed generates centrifugal force, which pushes the abrasive grains toward the leather surface. The pressure and friction on the leather surface determine the depth and precision of the sanding. By properly controlling the disc's speed, pressure, and rotational direction, the operator can achieve different sanding effects.

Indirect contact: Belt sanders and some specialized types of sanders utilize indirect contact. An abrasive belt is mounted between two rotating wheels and pulled by a drive system into contact with the leather surface. In this method, the belt's flexibility allows it to adapt to uneven leather surfaces, ensuring uniform sanding.

How it works: When the abrasive belt contacts the leather, the abrasive grains on the belt act as a cutter. Due to the belt's flexibility, the friction adjusts to the curvature of the leather surface, ensuring a more uniform sanding effect. Compared to traditional grinding wheels, belt sanders have a larger abrasive contact surface, making them suitable for sanding large, flat leather surfaces.

Differences in the Working Principles of Different Types of Sanders

While the core principle of all leather grinding machines is based on friction and cutting forces generated by mechanical power, different types of sanders differ in their applications and effectiveness due to their design, power source, and operating method. Common types of leather grinding machines include rotary sanders, vibrating sanders, and belt sanders, each with its own operating principles.

Rotary Sanders

Rotary sanders are the most common type. They use a rotating grinding wheel in direct contact with the leather, sanding it through friction. The grinding wheel is typically round and mounted on a motor shaft, which is driven by the motor to rotate at high speed.

Working Principle: The rotating grinding wheel rubs the leather surface at high speed, removing imperfections or unevenness while improving the leather's smoothness and feel. Rotary sanders are suitable for fine finishing requiring high surface finishes, especially for hard or thick leather surfaces.

Applications: This type of sander is widely used in leather products requiring high surface finishes, such as footwear and leather goods.

Vibratory Sanders

Compared to rotary sanders, vibratory sanders primarily transmit power through vibration. The abrasive disc or belt does not rotate at high speeds, but instead engages the leather surface through a reciprocating vibration.

Working Principle: Vibratory sanders generate friction through up-and-down or back-and-forth vibrations. This relatively low friction is suitable for gentle treatment of leather surfaces. The frequency and amplitude of the vibrations can be adjusted, allowing the operator to adjust the intensity and precision of the sanding according to the specific leather material.

Applications: Vibratory sanders are often used for leather products requiring delicate finishing and a high degree of surface smoothness, such as high-end leather goods and art leather.

Belt Sander

A belt sander uses a continuously rotating abrasive belt to sand leather. The belt's material and grit can be adjusted to suit your needs.

Working Principle: A belt sander uses a motor to drive the belt at high speed between two rollers. The belt, coated with abrasive particles, rubs against the leather surface, gradually removing the surface. Because the belt is relatively flexible, it can adapt to the curves of leather and is suitable for sanding large areas uniformly.

Application: This type of sander is suitable for fine-finishing large areas of leather, and is commonly used for initial rough sanding and medium-fine sanding.

| Type of Sander | Working Principle | Key Features | Typical Applications |

| Rotary Sander | Uses a rotating grinding wheel to rub the leather surface at high speed | High friction; suitable for fine finishing; ideal for hard or thick leather | High-surface-finish leather products, such as footwear and leather goods |

| Vibratory Sander | Uses up-and-down or back-and-forth vibrations to generate friction | Gentle treatment; adjustable frequency and amplitude; precise control | Delicate leather products, high-end leather goods, art leather |

| Belt Sander | Uses a continuously rotating abrasive belt driven by rollers | Flexible belt adapts to curves; suitable for large areas; medium to fine sanding | Large leather surfaces; initial rough sanding; medium-fine sanding |

Application of Leather Grinding Machines in Leather Surface Treatment

Leather grinding machines are crucial in leather surface treatment. They mechanically remove surface defects and unevenness, enhancing the appearance and feel of leather, and achieving a more refined and smooth finish. Traditional manual operations often make it difficult to maintain a consistent leather surface. The advent of leather grinding machines has solved this problem. Their precise grinding capabilities not only improve production efficiency but also enhance the quality of the finished product.

How Leather Grinding Machines Remove Defects and Irregularities from Leather Surfaces

Due to various factors during the production process, leather surfaces may develop various defects, such as bubbles, scratches, spots, and color variations. These defects and unevenness are particularly common in natural leather. Traditional manual grinding is often inefficient and difficult to achieve consistent results. The introduction of leather grinding machines provides an effective solution to this problem.

Leather grinding machines use high-speed rotating grinding discs, sanding belts, or other abrasives in contact with the leather surface, using friction and cutting forces to remove excess surface material. Specifically, the process of sanding leather to remove surface imperfections and unevenness can be divided into the following steps:

Surface Roughness Removal: Leather surfaces often have rough surfaces due to processing, dyeing, or natural grain. Sanding effectively removes these irregularities through coarse sanding (the first sanding step), resulting in a smooth and even surface.

Irregularity Correction: Natural leather imperfections such as bubbles, scratches, and color variations typically require fine sanding. Sanding machines can precisely adjust the pressure and depth of the sanding to minimize imperfections, ensuring a consistent and flawless leather surface.

Polishing and Glossing: The fine sanding and polishing functions of a sander can impart a certain gloss to the leather surface. By using finer abrasive belts or discs, sanders can finely refine the leather surface, creating a smoother, more textured finish and enhancing the leather's visual beauty.

Different Sanding Techniques (Rough Sanding, Fine Sanding, etc.) and Their Applications

Leather surface treatment isn't a single process; it typically involves multiple sanding stages to ensure high quality and consistency in the final leather product. Different sanding techniques utilize different abrasives, speeds, pressure, and other parameters tailored to the specific needs of the leather surface. Common sanding techniques include rough sanding, fine sanding, and polishing, each with its own specific applications and advantages.

Rough Sanding (Coarse Sanding)

Rough sanding is the first step in the leather sanding process, primarily used to remove rough surfaces, imperfections, or excess material. The goal of rough sanding is to create a smooth, even surface, preparing the leather for subsequent fine sanding and polishing.

Application: Rough sanding is suitable for removing larger irregularities, such as natural cracks, large imperfections, and oil or stains on the leather surface. For cut or punched leather products, rough sanding can also remove irregularities at the cut edge, ensuring smooth processing in subsequent processes.

Technical Features: Rough sanding typically uses a larger-grit sanding belt or disc, applying greater pressure to quickly remove thicker surface layers. While the leather surface is often still relatively rough at this stage, it lays the foundation for fine sanding and polishing.

Fine Sanding

Fine sanding is the second step in the leather sanding process. Its goal is to further refine the leather surface after rough sanding, making it smoother and more uniform. Fine sanding typically uses a finer-grit sanding belt or disc and applies less pressure. It aims to further eliminate minor irregularities left after rough sanding and ensure the leather's surface is delicate.

Applications: Fine sanding is suitable for removing surface irregularities that weren't completely smoothed out during rough sanding, addressing minor surface imperfections, and finely adjusting the leather's thickness and grain. The resulting leather surface is smooth and delicate, making it suitable for the next processing stage.

Technical Features: Fine sanding uses a finer-grit sanding belt or disc and applies relatively light pressure to ensure a smooth and uniform leather surface. After fine grinding, leather feels softer and is suitable for use in high-end products such as premium leather goods, footwear, and clothing.

Polishing

Polishing is the final step in the leather finishing process. Its purpose is to create a glossy, smooth surface, enhancing the leather's visual appeal and texture. Polishing often requires the use of ultra-fine abrasives, with relatively short pressure and time.

Application: Polishing is commonly used for the surface treatment of high-end leather products, such as luxury handbags, shoes, and car seats. For these products, the gloss and feel of the leather surface are crucial, and polishing effectively enhances their premium appearance and texture.

Technical Features: Polishing typically uses very fine abrasives or specialized polishing cloths to achieve the desired finish. Polishing is often combined with chemical agents (such as leather brighteners) to enhance the leather's surface brightness and durability.

Other Specialty Sanding Techniques

In addition to basic rough grinding, fine grinding, and polishing, leather grinding machines can also be used for specialized grinding techniques, such as grain grinding and spot finishing.

Grain sanding: Using specially designed sanding tools, leather surfaces can be polished to create unique textured effects, such as embossing or imitation leather grain. This technique is widely used in artistic leather goods, handmade leather goods, and high-end designer products.

Spot finishing: For small surface imperfections on leather, such as scratches or blemishes, sanding machines can precisely address these areas, avoiding over-sanding the entire surface and thus preserving the leather's integrity and aesthetics.

Comprehensive Application of Sanding Techniques

In actual production, various sanding techniques, such as rough sanding, fine sanding, and polishing, are often used in combination. Depending on the type of leather, the severity of the imperfections, the processing requirements, and the end use, operators need to flexibly adjust the sanding steps, tools, and parameters. For example, high-end leather goods usually go through three processes (rough grinding, fine grinding, and polishing) to ensure that the quality of the leather reaches the highest standards.

The Role of Leather Grinding Machines in Improving Surface Finish

The finish of leather is a key criterion for measuring its appearance, quality, and tactile feel. Highly glossy leather not only appears more refined visually but also provides consumers with a more comfortable feel. In the modern leather industry, leather surface finish is closely related to the polishing process, particularly the use of leather grinding machines, which directly determines the leather's smoothness, finesse, and overall aesthetics. Grinding machines play a vital role in improving leather surface finish. Proper polishing not only improves the appearance and feel of leather, but also enhances the overall quality and market competitiveness of leather products.

The Relationship between Leather Surface Finish and Grinding Machine Use

The surface finish of leather generally refers to the smoothness, gloss, and uniformity of the leather surface. During the leather processing process, leather is often affected by processes such as cutting, dyeing, and embossing, resulting in varying degrees of roughness, blemishes, and unevenness on the surface, all of which affect the leather's finish.

Improving the surface finish of leather is closely related to the polishing process. The sanding machine effectively removes excess particles, impurities, and irregularities from the leather surface, resulting in a smoother, finer surface and a desired sheen. By continuously adjusting factors such as the type of abrasive disc and belt, the grit size of the abrasive, and the sanding pressure, the sanding machine can precisely control the finish based on the specific characteristics of the leather and processing requirements.

Specifically, sanding machines help improve the leather's finish in the following ways:

Removing Surface Irregularities: The leather surface may have imperfections such as roughness and spots caused by uneven processing or dyeing. Through coarse and fine sanding, the sanding machine removes these irregularities and smoothes the leather surface.

Improving Gloss: Through fine sanding and polishing, the sanding machine creates a fine, smooth layer on the leather surface, enhancing its gloss. Especially when using fine-grained sanding belts or discs, the sanding machine produces a slight microscopic cutting action, resulting in a fine, lustrous surface.

Uniformity: Color and texture variations may occur on the leather surface due to differences in raw materials or processing. A sanding machine uses even pressure and precise sanding to even out the color and texture of leather, enhancing its overall aesthetics.

How Sanding Improves the Aesthetics and Tactile Feel of Leather

Sanding machines not only improve the appearance and glossiness of leather, but also finely alter its tactile feel, further enhancing its aesthetics. Different techniques and processes used in the sanding process can adjust the surface smoothness, softness, and glossiness of the leather, depending on the type and end use of the leather, thereby creating leather products that better meet market demands.

Rough Sanding vs. Fine Sanding: Basic Smoothing and Refining

Before sanding, leather typically undergoes preliminary processes such as cutting and dyeing. However, these processes may leave rough marks on the surface, affecting its glossiness and tactile feel. Rough sanding, the first step in sanding, aims to remove larger surface irregularities, such as blemishes and scratches, and smooth the leather surface. While this process effectively removes larger irregularities, the leather still appears relatively rough after rough sanding.

The fine sanding stage further refines the surface, removing tiny particles, minor flaws, and surface unevenness left behind by rough sanding. Fine sanding not only improves the smoothness of the leather but also creates a finer surface. After fine sanding, the leather surface becomes smoother, significantly enhancing its gloss and feel.

Polishing: Adding Gloss and Smoothness

Polishing is the final step in leather sanding, intended to further improve the gloss of the leather surface. Polishing creates a fine, smooth layer on the leather surface, giving it a mirror-like sheen. This not only enhances the leather's visual appeal but also makes it feel smoother to the touch.

During the polishing process, the leather surface is treated with fine abrasives. These tiny abrasive particles remove even the slightest surface irregularities, resulting in a smooth feel. Polishing also enhances the leather's durability and reduces surface damage caused by friction, ensuring that leather products retain their excellent appearance and feel even after prolonged use.

Detailed Processing: Improving Leather Texture

The grinding process not only improves surface finish but also significantly alters tactile feel. For example, in high-end leather products (such as luxury bags and shoes), the softness and finesse of the leather are crucial. Through precise grinding, the grinder can create a textured surface, making it softer to the touch and enhancing the consumer experience.

For specially designed leather products, the grinder can also create unique surface effects such as relief and embossed textures through precise grinding techniques. These detailed treatments not only enhance the leather's aesthetics but also impart a unique feel, satisfying personalized and artistic needs.

The Impact of the Grinding Machine's Diverse Functions on Leather's Aesthetics and Tactile Feel

Modern leather grinding machines offer a wide range of functions, allowing them to adjust the leather's surface finish, gloss, and tactile feel through various processes. Different types of grinding discs, sanding belts, and grinding pressure and speed allow for precise control of the grinding effect. For example, a fine-grained abrasive belt can achieve meticulous finishing, enhancing the smoothness of the leather surface; whereas a coarser abrasive belt is suitable for leather with larger surface defects, achieving a more uniform finish through coarse grinding.

The leather grinding machine's operational flexibility allows it to adapt to the surface treatment of different leather materials and product requirements. Whether it's uniformly treating large areas of leather or refining localized defects, a grinding machine provides an efficient and precise solution.

Role in Leather Quality Control

In the leather production process, quality control is a critical step in ensuring that products meet market demand and customer expectations. Leather quality depends not only on the selection of raw materials and the initial processing, but is also closely related to subsequent surface treatment and polishing processes. As a key piece of equipment in modern leathermaking, the leather grinding machine, with its efficient and precise grinding capabilities, plays a vital role in quality control. It effectively ensures consistent polishing quality, precisely controlling the thickness, flatness, and detailing of the leather, thereby ensuring the high quality and stability of the final leather product.

How does a leather grinding machine ensure consistent polishing quality?

The leather grinding machine eliminates the quality fluctuations that can occur with traditional manual polishing through an automated and standardized polishing process. Manual polishing relies on the operator's skill and experience, which is easily affected by the operating environment, tool wear, and human factors, resulting in variations in polishing quality from piece to piece. Leather grinding machines ensure consistent grinding quality through the following methods:

Automated Control System: Modern leather grinding machines are mostly equipped with automated control systems that precisely adjust parameters such as grinding speed, pressure, abrasive particle size, and grinding depth. This ensures consistent grinding conditions for each grinding cycle, ensuring consistent and consistent results. The automated system can also adjust the grinding machine's operating mode based on different leather types and processing requirements, ensuring that each batch of leather is processed to the same standard.

Precision Grinding Disc and Belt Design: Grinding discs and belts are typically manufactured using high-precision processes to ensure consistent performance during the grinding process. Precision grinding discs and belts not only reduce uneven wear on the leather surface but also provide the appropriate grinding force for varying leather thickness and surface condition. This stable grinding force is key to consistent grinding quality.

Uniform Pressure Distribution: Leather grinding machines achieve uniform pressure distribution during the grinding process, eliminating the common problems of over- or under-grinding with manual grinding. Whether through the even pressure of the grinding disc or the precise adjustment of the sanding belt, the grinding machine ensures uniform force across the leather surface, resulting in consistent grinding results.

Intelligent Detection and Feedback System: Some high-end leather grinding machines are equipped with an intelligent detection and feedback system that monitors the leather surface condition in real time during the grinding process. When the system detects abnormalities on the leather surface (such as excessive wear or unevenness), it automatically adjusts the grinding machine's operating parameters to ensure optimal grinding quality for each piece of leather. This feedback mechanism further improves the consistency of grinding quality.

The Importance of Leather Grinding Machines in Controlling Leather Thickness

Leather thickness has a significant impact on the quality and lifespan of the final product. Leather that is too thick may result in an excessively hard finish, affecting comfort; while leather that is too thin may result in breakage or poor durability. Therefore, precise control of leather thickness is crucial, and leather grinding machines play a key role in this regard.

Finely Adjusting Grinding Depth: A key feature of a leather grinding machine is its ability to finely adjust the grinding depth. By controlling the distance between the grinding disc and the leather surface, and adjusting the grinding time and speed, the grinder can fine-tune the leather surface layer by layer as needed, precisely removing excess material and ensuring that each piece of leather meets the designed thickness standard. Especially in the initial stages of leather grinding, the grinder can quickly and evenly remove irregularities on the leather surface, ensuring consistent thickness across the entire piece.

Adapting to Different Leather Thickness Requirements: Different types of leather have varying thickness requirements. For example, high-end leather goods may require a thin, uniform leather, while certain handicrafts may require thicker leather. A leather grinding machine can flexibly adjust its grinding strategy based on the thickness requirements of each leather. By setting the appropriate grinding pressure and speed, the grinder ensures consistent results even across leathers of varying thicknesses, preventing areas of excessive thickness or thinness.

Avoid Over-Grinding: Over-grinding can cause leather to become thinner, affecting its durability and aesthetics. Leather grinding machines, with their precise grinding control system, prevent excessive wear during the grinding process. During the grinding process, the equipment precisely monitors and controls the thickness variations of each piece of leather, preventing damage caused by over-grinding.

The Importance of Leather Grinding Machines in Smoothness Control and Detail Treatment

The smoothness of leather has a significant impact on its appearance and performance. Any surface irregularities will affect the appearance of leather products, especially in high-end leather goods, where surface smoothness is particularly important. Leather grinding machines play a particularly important role in this regard, helping tanners effectively control the smoothness and detail treatment of leather, ensuring the highest quality.

Smoothness Control: Leather smoothness generally refers to whether the surface is smooth and free of wrinkles or protrusions. Leather grinding machines, through efficient grinding disc rotation and precise pressure regulation, can remove even the smallest surface irregularities. Especially in large-scale leather production, manual grinding often fails to guarantee the smoothness of every piece of leather. Grinding machines, however, can maintain consistent results across mass production, eliminating surface unevenness caused by human error.

Detail Processing and Local Refining: Leather grinding machines not only address large-scale surface smoothness issues but also precisely refine local details. For minor surface imperfections on leather, such as tiny scratches and spots, grinding machines can repair them through meticulous grinding. Through fine grinding and polishing, grinding machines can remove minor imperfections while maintaining the leather's delicate finish.

Compatible with Complex Textures: Modern leather grinding machines are capable of grinding not only smooth leather but also leather materials with complex textures.

For example, leather with special textures, such as imitation leather and embossed leather, often requires a more demanding grinding process. Leather grinding machines can adjust the grinding method based on the leather's surface structure and texture characteristics, enhancing smoothness and fineness without damaging the original texture. This is crucial for the production of high-end leather goods.

Improving Production Efficiency

With the global leather industry's ever-increasing demands for both production volume and quality, improving production efficiency has become a key goal for companies. Traditional leather grinding processes primarily rely on manual labor. While these processes can achieve certain quality standards, they have significant limitations in terms of production efficiency, cost control, and consistency. The introduction of leather grinding machines not only effectively addresses these issues but also significantly improves efficiency in large-scale production, reduces labor costs, and provides leather companies with greater production flexibility and competitiveness.

How Leather Grinding Machines Replace Manual Grinding

Manual grinding is a common process in traditional leather processing. While it can achieve a fine finish on the leather surface, it has several drawbacks. First, manual grinding is time-consuming and labor-intensive, and the operator's experience and skill directly impact the quality of the grinding, making it difficult to ensure consistent quality across batches of leather. Second, manual grinding is inefficient, especially in large-scale production, and cannot meet the market's demand for high output and high quality.

In contrast, leather grinding machines, with their efficiency and automation, are becoming an ideal alternative to manual grinding. Leather grinding machines can process large quantities of leather in a short period of time, ensuring highly consistent production speed and polishing quality. Specifically, the advantages of leather grinding machines are primarily reflected in the following aspects:

High-Speed Production

A significant advantage of leather grinding machines is their high production speed. Through mechanized and automated operation, grinding machines can process large quantities of leather in a given period of time. Compared to manual grinding, grinding machines not only increase grinding speed but also enable continuous operation, eliminating the pauses and rest periods required for manual operation. In large-scale production, grinding machines can significantly shorten production cycles and significantly improve production efficiency.

Consistency and Stability

In traditional manual grinding, variations in operator skill, experience, and physical strength lead to variations in the polishing quality of each piece of leather. This not only affects the product's appearance, but also increases the likelihood of rework and reduces production efficiency. Leather grinding machines, on the other hand, utilize automated control systems to ensure highly consistent parameters such as grinding depth, speed, and pressure for each piece of leather. This way, whether for large-scale production or processing different types of leather, the grinding machine ensures stable and consistent grinding results, eliminating the quality fluctuations that can occur with manual operation.

Reducing Human Error

Manual operation inevitably leads to errors such as missed grinding, over-grinding, or uneven grinding. These problems can affect leather quality and even require reprocessing, increasing costs and time. The leather grinding machine, however, eliminates the possibility of human error through precise CNC control of the workflow. The system monitors and adjusts the process in real time to ensure that every piece of leather meets production requirements.

Advantages of Reducing Manual Operation and Improving Work Speed

The introduction of the leather grinding machine not only reduces reliance on manual operation but also increases work speed, bringing numerous production benefits. The following are some of the key advantages of the leather grinding machine in reducing manual operation and increasing work speed:

Reducing Labor Costs

Manual grinding requires a significant amount of labor, especially in production lines that process large quantities of leather. Labor costs are a significant expense. Manual grinding workers incur not only wages but also training and occupational health insurance costs. By introducing leather grinding machines, companies can effectively reduce the need for manual labor and human resource investment. This significantly improves production efficiency while significantly reducing labor costs and boosting overall profits.

The automated operation of leather grinding machines reduces the company's need for employees, allowing them to be more effectively deployed in other areas, further optimizing the human resource allocation of the production line. With increased automation, the company's overall operating costs are effectively controlled, significantly reducing production costs.

Increasing Work Speed and Output

Leather grinding machines operate much faster than manual operations. Through mechanization and automation, leather grinding machines can complete large-scale grinding tasks in a short period of time, significantly improving production line efficiency. For example, some high-efficiency grinding machines can process over 300 square meters of leather per hour, while manual grinding can only process approximately 30 square meters in the same amount of time. As grinding machine technology continues to advance, operating speeds will continue to increase, further boosting production line output.

The leather grinding machine's ability to operate continuously also significantly improves production efficiency. Manual grinding often requires operators to rest and adjust, while a grinding machine can operate continuously for 24 hours without rest, allowing more leather to be processed in the same amount of time, further increasing production capacity.

Improving Production Flexibility

As market demand fluctuates, the production batches and specifications of leather products also adjust. The introduction of leather grinding machines allows production lines to more flexibly respond to these changes. By pre-setting different parameters, the grinding machine can automatically adjust the grinding method based on the different characteristics of the leather, such as material, thickness, and texture, quickly switching to different production modes. Compared with manual operation, the grinding machine offers greater flexibility in responding to different product requirements and can quickly adapt to changing production needs.

Improving Worker Efficiency and Safety

The use of leather grinding machines reduces worker labor intensity and fatigue. Traditional manual grinding is not only laborious but also prone to fatigue due to long periods of repetitive work, increasing the risk of operator error and injury. Leather grinding machines, on the other hand, automate most of the grinding tasks, significantly reducing the workload for workers. At the same time, mechanized operations can also reduce the impact on worker health, particularly by preventing occupational illnesses caused by grinding dust and harmful gases. The use of leather grinding machines improves worker efficiency and safety, creating a more user-friendly work environment.

Comprehensive Benefits of Improved Production Efficiency

The role of leather grinding machines in improving production efficiency is not only reflected in reduced production speed and labor costs, but also brings a series of other comprehensive benefits:

Shortened Delivery Time: Due to the significant increase in production speed, companies can respond to market demand more quickly and shorten delivery time. This is crucial for meeting urgent orders and increasing customer satisfaction.

Improved Product Consistency: Grinding machines ensure the consistency of each batch of leather, improving product quality control and enhancing brand competitiveness.

Increased Production Capacity and Increased Market Share: Increased production efficiency enables companies to expand production and capture a larger market share, thereby increasing market share and profits.

简体中文

简体中文 English

English عربى

عربى